Description

DJ Pump Engine Cooling Pumps and Impellers

For over 30 years DJ Pump has been manufacturing and supplying the marine industry with quality marine pumps and accessories. DJ Pump impellers are manufactured in their hi-tech Korean ISO certified facility to exacting standards ensuring consistent quality and reliability. The range of DJ Pump impellers are subjected to quality testing to ensure reliability and continued performance.

About flexible impeller pumps

Flexible impeller pumps are used extensively in the marine industry and are designed to provide an efficient method of pumping raw water to a large number of applications where required. Often an integral part of the engine cooling system, these pumps operate using an internal impeller which is designed to circulate water continuously throughout the engine.

To satisfy the replacement market DJ Pump manufactures a wide range of popular impeller vane and shaft configurations in neoprene for general fresh and seawater applications and, to a lesser extent, in nitrile for oil and diesel applications. DJ Pump impellers can be fitted to most makes and models of flexible impeller marine engine cooling, bilge, electronic clutch and multi-purpose pumps and are manufactured from quality materials to provide excellent longevity without sacrificing flow characteristics.

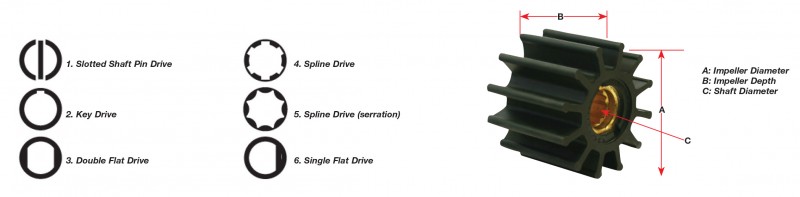

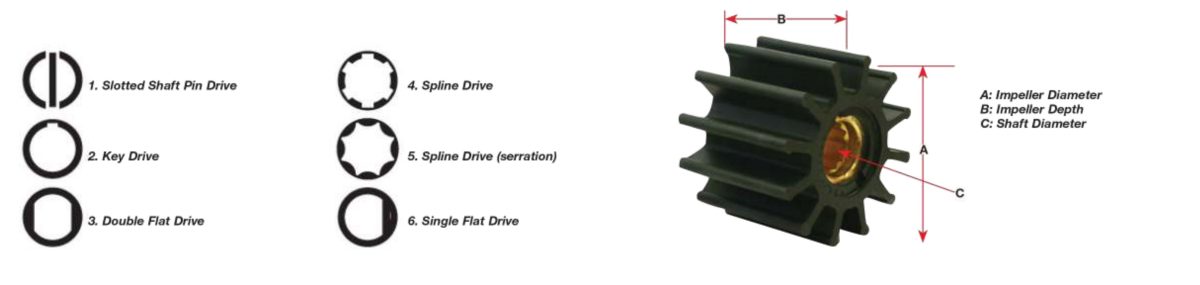

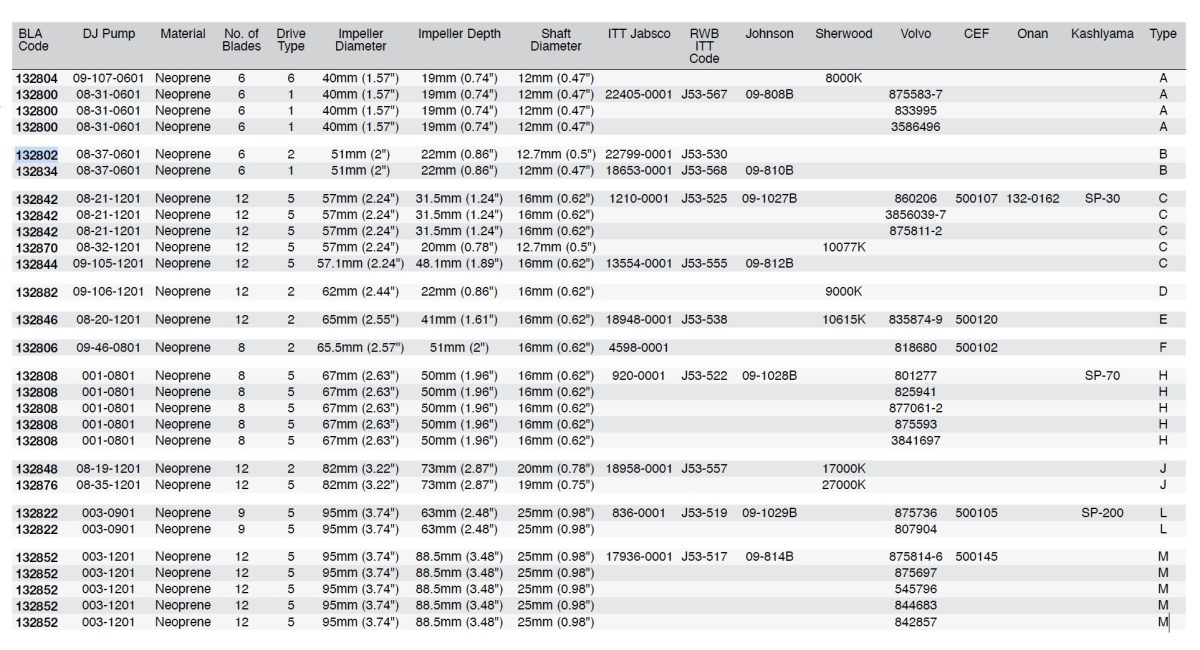

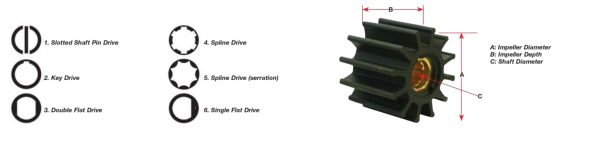

Available in a wide range of shaft, diameter and depth configurations each impeller is packed in an easy to identify box clearly showing shaft, material and brand replacement codes.

Warning: The impeller is a very important security device. Its task is to pump the water through the cooling system of the engine. Replace the impeller at least once every year, or sooner depending on engine duty. Always carry a spare impeller on board.

DJ Pump Impeller 08-31-0601 — Specifications

- DJ Pump: 08-31-0601

- No. of blades: 6

- Drive type: 1

- Impeller diameter: 40 mm (1.57″)

- Impeller depth: 19 mm (0.74″)

- Shaft diameter: 12 mm (0.47″)

- Material: Neoprene

- Type: A

Compatibility

DJ Pump Impeller 08-31-0601 suits the following models:

- ITT Jabsco: 22405-0001

- RWB ITT Code: J53-567

- Johnson: 09-808B

- Volvo: 875583-7, 833995, 3586496

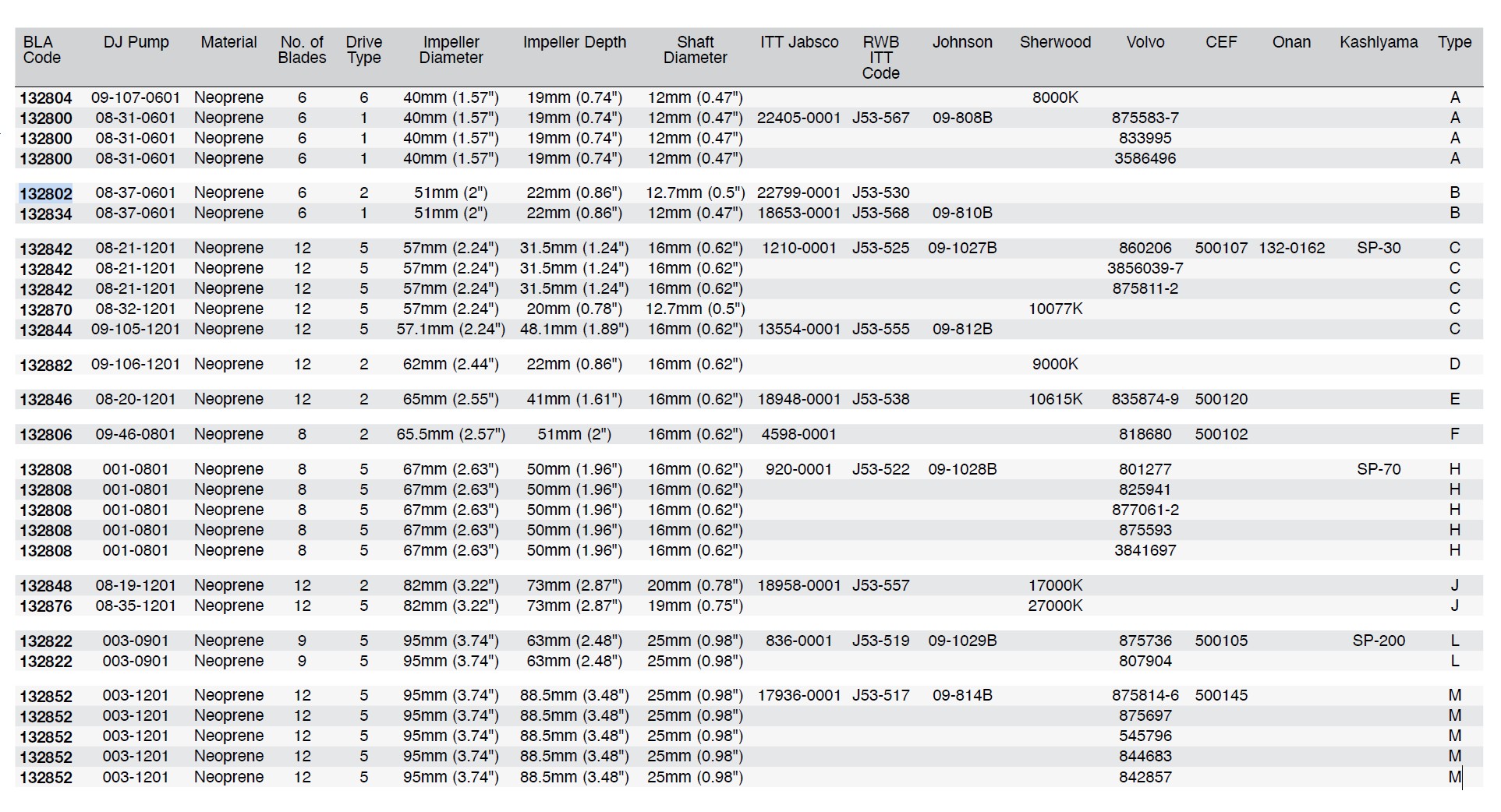

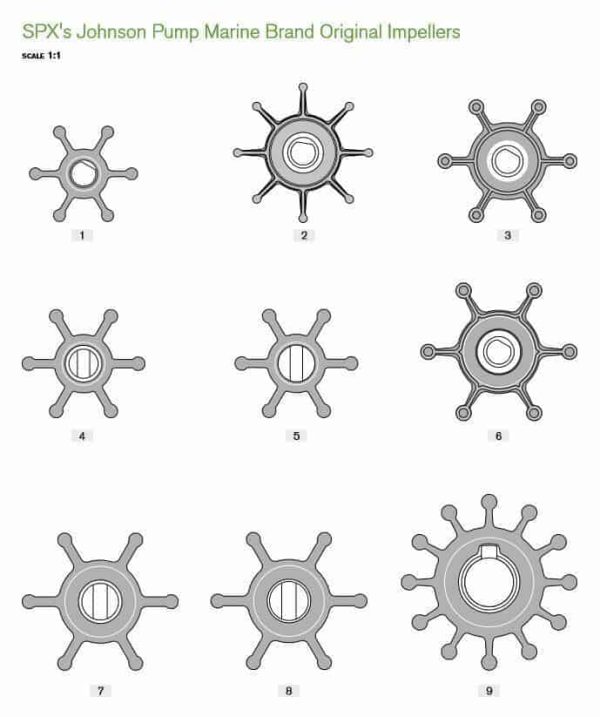

Please refer to the DJ Pump Impeller Reference guide for other information about the DJ Pump Impeller range.

Material guidance

- Neoprene impellers — Use for engine cooling, and for fresh or salt water transfer duties. Neoprene is the most commonly used material and is suitable where only small amounts of oil or diesel fuel are present.

- Nitrile impellers — Use for bilge pumping and for transfer duties where the water is heavily contaminated (for example by oil or diesel).

Installation & maintenance tips

- Replace impellers at least once every year, or sooner depending on engine duty. When the installation is correct an impeller may last several years, however preventative maintenance is recommended.

- To remove the impeller: remove the end cover screws and use an impeller removal tool or channel lock pliers (slip joint pliers) to grip the hub of the impeller. Do not use screwdrivers — they can damage the pump face and cause leaks, and can be dangerous in confined spaces.

- Always grease new impellers. Greasing makes installation easier and gives added protection during initial prime.

- After fitting the new gasket and end cover, the pump is ready to use.

Always carry spare impellers on board in case of emergency. The impeller is one of the most vital components of the engine cooling system and should always be treated as such.

DJ Pump Impeller 08-31-0601 — Pump Impeller Shop

Boat Hut Insight

When replacing an impeller, fit it dry only if the manufacturer specifies it — otherwise lightly grease the hub and vanes to help installation and initial priming. A practical trick many cruisers use: mark the shaft orientation and the face of the old impeller before removal. This helps you spot uneven wear or foreign debris grooves on the pump housing that could indicate a blocked sea strainer or cooling passage upstream. If you find deep scoring on the housing, replace the housing or fit a repair sleeve — a new impeller on a damaged bore will still leak or fail prematurely. Finally, pair a fresh neoprene impeller with a strainer clean-out check on every haul-out; most failures trace back to blocked strainers or air leaks on the suction side rather than the impeller compound itself.

DJ Pump: 08-31-0601 No. of Blades: 6 Drive Type: 1 Impeller Diameter: 40mm (1.57") Impeller Depth: 19mm (0.74") Shaft Diameter: 12mm (0.47")

Reviews

There are no reviews yet.